Machinery is a fundamental component of any manufacturing facility, playing a critical role in determining production costs and the final price of goods. The influence of machinery on these aspects extends both directly and indirectly to the broader micro and macroeconomic landscape.

Impact on Production Costs

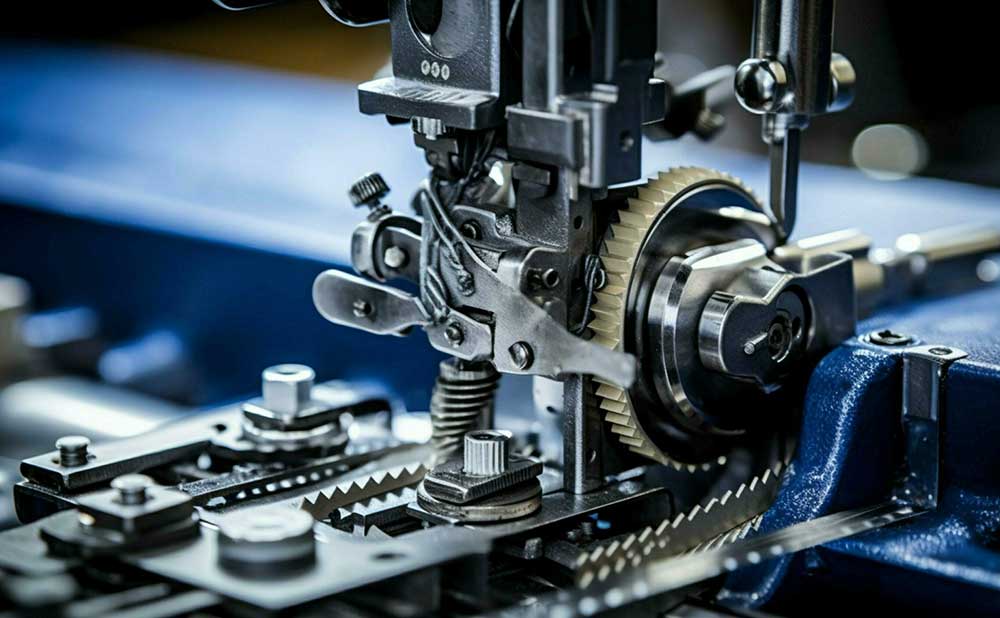

The acquisition, maintenance, and operation of machinery represent significant investments for any manufacturing plant. High-quality, efficient machinery can increase production capacity, reduce waste, and lower labor costs, leading to a more competitive pricing structure for the factory’s output. However, the initial capital expenditure on advanced machinery can significantly impact the overall production costs. This investment, though substantial, often leads to long-term savings and higher profitability due to increased efficiency and reduced downtime.

Moreover, the choice between purchasing new machinery versus second-hand equipment can also affect the cost structure. New machinery typically offers better efficiency and longer service life, but at a higher upfront cost. On the other hand, used machinery may offer short-term savings but could lead to higher maintenance costs and shorter operational lifespan, ultimately affecting the factory’s bottom line.

Impact on Microeconomics

At the microeconomic level, the impact of machinery is seen in the operational efficiency and profitability of individual businesses. Efficient machinery can reduce production costs, allowing companies to offer competitive prices, improve profit margins, and increase their market share. This, in turn, can lead to increased demand for the company’s products, creating a positive feedback loop of growth and investment.

On the flip side, small and medium-sized enterprises (SMEs) may struggle with the high costs of acquiring and maintaining advanced machinery, which could limit their ability to compete with larger firms that have more capital to invest in state-of-the-art technology. This dynamic can lead to market consolidation, where larger firms dominate the market, potentially stifling competition and innovation in the long term.

Impact on Macroeconomics

From a macroeconomic perspective, machinery plays a pivotal role in driving industrial productivity and economic growth. Investments in modern machinery are often associated with increased production capacity, which contributes to higher GDP and economic output. Additionally, as factories adopt more advanced machinery, the overall efficiency of the manufacturing sector improves, leading to lower production costs and reduced prices for consumers.

Furthermore, the demand for machinery spurs growth in related industries, such as manufacturing of machine tools, robotics, and industrial automation. This interconnection boosts employment and stimulates economic activity across multiple sectors. However, the shift towards automation and advanced machinery can also have a negative impact on employment in traditional manufacturing roles, potentially leading to job displacement and requiring a shift in workforce skills.

In conclusion, machinery significantly impacts both the micro and macroeconomic environments. For factories, it is a crucial factor in determining production costs and pricing strategies, while at the broader economic level, it drives productivity, innovation, and economic growth. Balancing the costs and benefits of investing in machinery is essential for businesses and economies to thrive in a competitive global market.